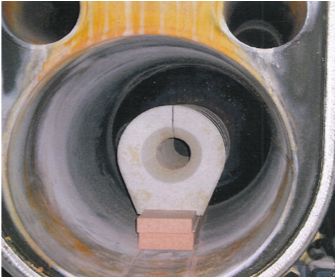

HTS Hochtemperatur-Speicher

HTS Hochtemperatur-Speicher aus Keramik sind in der Praxis für den Einsatz bei Heizanlagen seit 2006 erprobt und werden seitdem erfolgreich eingesetzt. Es ist ein Produkt zur Speicherung von Flamm- bzw. Wärme-Energie und kann in jedem Öl- oder Gas-Heizkessel einer Heizung mit horizontalem Gebläsebrenner eingesetzt werden.

Sparpotential:

Der Einbau von HTS Hochtemperatur-Speichern reduziert den Brennstoffverbrauch, je nach Typ und Betriebsweise der Anlage um 6% – 25%.

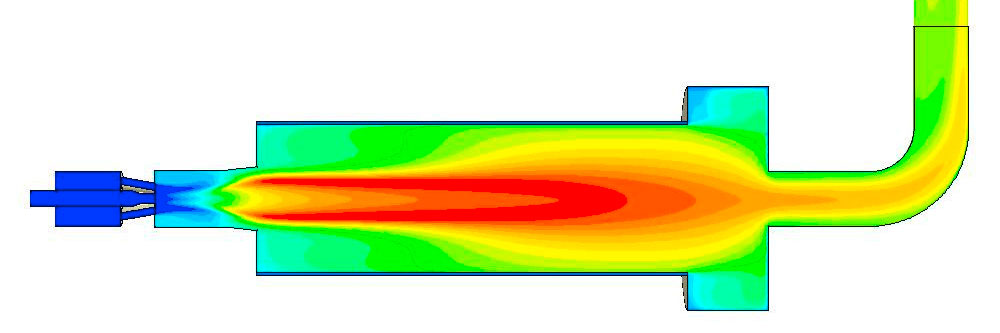

Die Wirkungsweise ist sowohl einfach wie effektiv. Der HTS Hochtemperatur-Speicher wird durch die Flamm-Energie während der Brennerlaufzeit aufgeheizt. Nach Abschalten des Brenners sinkt normalerweise die Kesseltemperatur unmittelbar und rapide.

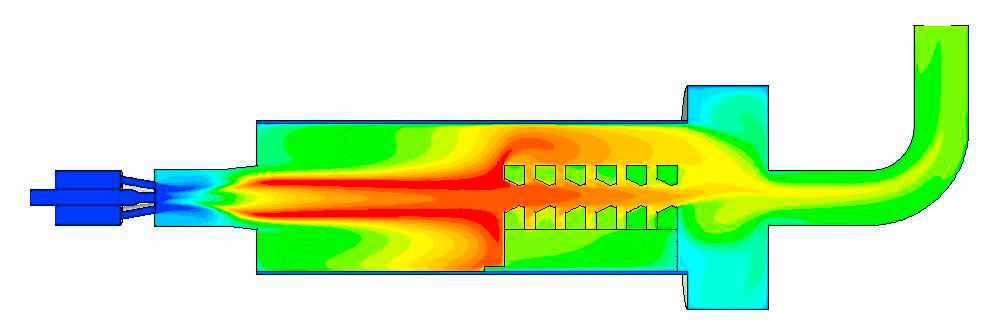

Mit dem HTS Hochtemperatur-Speicher hingegen, wird nach Abschalten die gespeicherte Wärmeenergie kontinuierlich weiter an den Heizkessel abgegeben. Dadurch wird das wiederholte Zuschalten des Brenners extrem verzögert und die Stillstandzeiten des Brenners werden so erheblich verlängert.Dies spart Energie und reduziert die Betriebskosten des Brenners nachhaltig.

Kessel ohne HTS Hochtemperatur-Speicher

Kessel mit HTS Hochtemperatur-Speicher

Weitere Effekte, die zur Reduzierung beitragen, sind die Umlenkung der Hitzeströme an die Kesselwände und daraus folgend der bessere Wärmeübergang sowie die turbulente Strömung, welche zu einer verbesserten Verbrennung der Gase führt. Das bringt nicht nur Einsparungen beim Verbrauch, sondern senkt auch im starken Masse die Emissionen.

Die genannten Effekte werden durch die Studie des Gas Wärme Instituts, Essen (GWI) bestätigt. Es liegen auch Schreiben des TÜV SÜD vor, die belegen, dass durch den Einbau dieser Technologie auch nach Jahren keine Schäden an Kessel oder Brenner bekannt geworden sind.

Referenz- und Testinstallationen

Installation der HTS Hochtemperatur-Speicher

Die Installation der Hochtemperatur-Speicher erfolgt innerhalb weniger Stunden.

Grosse Kessel sollten wenigstens einen Tag auskühlen, damit der Brennraum begehbar ist. Um Produktionsunterbrechungen zu vermeiden, kann die Installation auch am Wochenende stattfinden.

Die Installation erfolgt vorzugsweise nachdem der Kaminfeger den Heizkessel gereinigt hat und der Brenner abgeschaltet ist.

Nach erfolgter Installation kann die Anlage wieder wie gewohnt in Betrieb genommen werden.

Installations-Beispiele

- Villa Sommerlath (Bruder der Königin Silvia von Schweden)

- Hotel Alpina, Klosters

- Hotel Glockenhof, Zürich

- Brauerei Waldhaus, Schwarzwald

- und viele mehr

Sauber. Sparsam. Effizient.

Fordern Sie heute noch Ihre unverbindliche Offerte an oder nehmen Sie mit uns Kontakt auf. Wir sind gerne für Sie da.